IRON ORE PROCESSING PLANT YouTube

Oct 27, 2011· IRON ORE PROCESSING PLANT durgagodugu. Loading... Unsubscribe from durgagodugu? ... Minnesota Iron Mining Process Duration: 6:15. Minnesota Iron 148,051 views. 6:15.

WhatsApp)

WhatsApp)

Oct 27, 2011· IRON ORE PROCESSING PLANT durgagodugu. Loading... Unsubscribe from durgagodugu? ... Minnesota Iron Mining Process Duration: 6:15. Minnesota Iron 148,051 views. 6:15.

Feb 26, 2018· gold trommel wash plant is for washing clay ore, this drum scrubber washer can wash all kinds of sticky clay material, include: alluvial gold / tin ore/ tungsten ore/ chrome ore/ coltan ore ...

IRON ORE SALIENT DATA OF ORE DRESSING INVESTIGATIONS CARRIED OUT DURING BY ORE DRESSING DIVISION, INDIAN BUREAU OF MINES SR. CONCENTRATE NO. NO. TITLE OF THE INVESTIGATION ORIGINAL ANALYSIS % MINERALOGY WT% ASSAY% %REC PROCESS ADOPTED The specific surface area of three iron ore samples is as follows Sr. No. Jindal .

Magnetite (Fe3O4), like hematite (Fe2O3), is a form of iron ore. It is a benign and highly magnetic substance used primarily in steel manufacturing and coal washing. Magnetite occurs in nearly all igneous and metamorphic rocks and usually only in small particles or in a solution with other minerals. Some beaches, often called black sand beaches,

The majority of Earth''s iron, however, exists in iron ore. Mined right out of the ground, raw ore is mix of ore proper and loose earth called gangue. The ore proper can usually be separated by crushing the raw ore and simply washing away the lighter soil.

Aug 26, 2016· Shenbang stone crushing equipment is designed to achieve maximum productivity and high reduction attrition scrubber used in iron ore processing plants attrition scrubber used in iron ore ...

The most common commerciallyviable iron ores are iron sulphide and iron oxide. Sulphide ores are "roasted" to convert them into oxide. Formerly, the exhaust gasses were vented (contributing to acid rain), but now must be run through a "scrubber"....

Ore Washing Plant IndustrialCraftWiki. If you have seemly unlimited power then it makes sense but until then the 4 extra iron might not be worth the cost Note: You can only get uranium from a thermal centrifuge and not the ore washing plant! Well, that''s what the centrifuge is for For long work without overflow you need 10 ore washing,...

Many iron ore producers are facing challenging times due to price uncertainty and the need to process crude material with increasing levels of impurities. Upgrading the ore through beneficiation processes, particularly washing (scrubbing), to earn more per shipped tonne can be the key to improving ...

The only commercial technology solution currently available to meet compliance with MARPOL Annex VI Regulation 14 is an exhaust gas cleaning system, namely scrubbing. Remember Regulation 14 ...

scrubber for iron ore | Solution for ore mining. Apr 23, 2013· how does scrubber works in iron ore washing – Articles Crusher Machine. how does scrubber works in iron ore washing; what method is suitable for separating iron from crushed copper ores; grinding mill . Blast furnace – Wikipedia, the free encyclopedia.

Apr 23, 2013· how does scrubber works in iron ore washing – Articles Crusher Machine. how does scrubber works in iron ore washing; what method is suitable for separating iron from crushed copper ores; grinding mill . Blast furnace – Wikipedia, the free encyclopedia. Iron ore deposits were often donated to the monks . while the gas ...

rapid wear of the rubber lining and irregular wash water distribution resulted in major production problems. Although still in use, the Humphreys cast iron spirals have been largely superseded by a variety of other types, notably the fiberglass Reichert spirals and new, lightweight Humphreys spirals.

the blast furnace productivity, significant improvement in the quality of the iron ore is required. To meet a parts of this enhanced requirement of iron ore, both in terms of quantity and quality, a process audit study was undertaken at Joda Iron ore washing plant. The

In iron ore mining, miner usually choose a complete iron ore crushing plant for metallurgy. Iron ore beneficiation process. Almost all of the iron ore that is mined is used for making steel. So we need the extraction of a pure metal from its ore. The extract the metal from ores, several physical and chemical methods are used.

MIKROPUL WET SCRUBBERS MikroPul has been a pioneer worldwide in providing wet scrubbers to solve air pollution control problems for over 40 years. We offer five principal designs customizable to meet your requirements: • MikroVane scrubber with no moving parts • Dynamic scrubber with integral fan • High efficiency venturi scrubber

Heat speeds up the reaction, as does agitation. If you have a hot plate and can set up outdoors or in an area with good ventilation the repeat step 4 but heat the solution to bath water hot (110o f.). Never Boil! You will find that an hour in hot solution will usually do the trick. Best of all is an ultrasonic cleaner .

Iron Mining and Processing in South Africa RESOUR CE PA CK Iron Mining and Processing in South Africa Source: Kumba Iron Ore, UNIVERSITY OF CAPE TOWN IDYUNIVESITHI YASEKAPA • UNIVERSITEIT VAN KAAPSTAD Road construction / concrete manufacture Crushing Open pit mining is used to excavate iron ore that is close to the surface.

The ASGCO® Wash Box™ Belt Cleaning System is installed as a secondary belt cleaner and is designed to work on the return side of the conveyor belt. The ASGCO® Wash Box™ Belt Cleaning System is installed as a secondary belt cleaner and is designed to work on the return side of the conveyor belt. ... Mining, Steel Mills, Iron Ore, Mineral ...

Home>product>how does scrubber works in iron ore washing This Chainmail Scrubber Makes Cleaning a Cast Iron Skillet Effortless Dec 26, 2017 This scrubbing tool will change the way you use your cast iron skillet of your cooking and works to flavor every single dish you make in it.

Aug 25, 2016· Shenbang stone crushing equipment is designed to achieve maximum productivity and high reduction attrition scrubber used in iron ore processing plants attrition scrubber used in iron ore ...

HOW A BLAST FURNACE WORKS Introduction The purpose of a blast furnace is to chemically reduce and physically convert iron oxides into liquid iron called "hot metal". The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into the top, and preheated air is blown into the bottom.

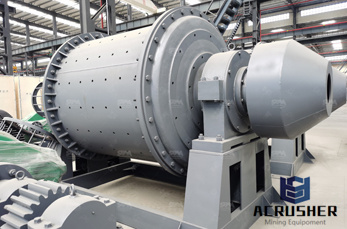

Attrition Scrubbers Provide Intense Scrubbing Action at Densities of 70%80% Solids. The Attrition Scrubber provides a simple, economical solution to many of today''s beneficiation problems. Many products can be made marketable by the removal of surface films, coatings or slimes.

The volume occupied by the solids is the ''struck'' volume of the scrubber (set by the diameters of the scrubber and the outflow ) plus the solids surcharge set by the volumetric flow of the solids over the circular outflow . This second volume is not often taken into account when comparing or calculating scrubber residence times.

WhatsApp)

WhatsApp)