PAI SAG Mill Training YouTube

Jan 08, 2016· In this training module, we''ll cover the workings of a semiautogenous grinding mill, or SAG mill, that''s designed to be the first stage of a grinding circuit. Ore that''s crushed in a primary ...

WhatsApp)

WhatsApp)

Jan 08, 2016· In this training module, we''ll cover the workings of a semiautogenous grinding mill, or SAG mill, that''s designed to be the first stage of a grinding circuit. Ore that''s crushed in a primary ...

Table of Contents Autogenous Grinding CircuitsSAG vs Ball Mill AdvantagesAG SAG Mill Grinding Compared – Which is BestTesting for Product Size Size reduction is the most expensive operation in most mills. Crushing and grinding usually require the greatest portion of capital costs and often make up 6070 percent of total mill operating costs as shown in Figure 1.

ness of the models. For a given mill to have a combination of feed size, ball load, mill speed and % solids will represent the total load. Ball Mill SAG Mill Scw Jb Pc % 6" +1" N/Nc Fresh Feed Water Water Pebble Crusher Screen Cyclones Sump Pump Fig. 1. SABC A/B milling circuit.

Jan 19, 2016· The mills at Sentinel in Zambia are amongst the world''s biggest, with 2 off 40 ft SAG mills complete with 28 MW drives, and 2 off 28 football mills .

acidresistant mills for grinding in raffinate or with acidforming feed, as well as special feed and discharge arrangements and special bearing arrangements. Outotec SAG and ball mill Outotec highperformance grinding mills use advanced simulation tools for the best possible process efficiency, mechanical reliability, and maintainability.

The SAG Mill is a block added by the EnderIO mod. A machine similar to a Pulverizer or a Macerator. It is used to process resources to produce dust. It accepts energy in the form of Redstone Flux or Minecraft Joule, with an internal buffer of .

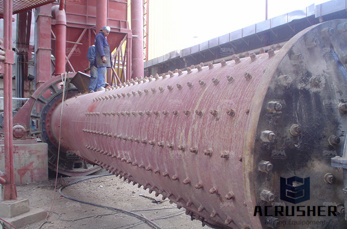

SAG is an acronym for semiautogenous grinding. SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. The largest SAG mill is 42'' () in diameter, powered by a 28 MW (38,000 HP) motor.

SAG mills mimic the same shortcoming. It follows that in order to obtain the specifi c energy (SE) to achieve a certain transfer size, based on the 80 per cent passing value, an ineffi ciency factor must be applied to the SE of single stage ball mills, rod mills or AG/SAG mills when calculating power according to the Bond Third Theory method.

> BALL CHARGING SYSTEMS. BALL CHARGING SYSTEMS. ... are consumed by all process plants having mills as part of their comminution process. Transmin has a range of systems available to safely store and feed balls from simple kibbles through to complex handling systems. //AUTOMATED BALL CHARGERS //BALL CHARGERS //DRUM KIBBLES //ENGINEERING ...

The Selection and Design of Mill Liners . ... Was generally used for mill liners (AG, SAG and Ball) prior to the movement to higher carbon content steels. It has excellent wear characteristics with some impact resistance, generally now used for discharge grates where

Model Predictive Control for SAG Milling in Minerals Processing | 5 Model Predictive Control on a SAG Mill and Ball Mills The solution for the SAG Mill is an adaptive controller which controls mill load using direct mill weight measurement or indirectly from bearing oil pressure.

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

xG is the mill feed d80, not the circuit feed. For SAG mill, the xG value has to be determined by scalping of the full size distribution. The particles larger than the minimum pebble size (given by the pebble extraction grate opening) has to be excluded from the distribution to calculate the top ball size!

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

Nov 12, 2014· 3D Animation Demo working site of Ball Mill Henan Bailing. Loading... Unsubscribe from Henan Bailing? Cancel Unsubscribe. Working... Subscribe Subscribed Unsubscribe

length(m)) following two parallel ball mills (5dia.(m)*7lenght(m)). The aim of this research work was to investigate on the ball filling estimation of Miduk semiautogenous (SAG) Mill via an utilized method. Miduk SAG Mill circuit is shown in Figure 1. Figure 1: Diagram of Miduk Copper Complex SAG Mill Methods

AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill. Because of the range of mill sizes available, AG/SAG milling can often be accomplished with fewer lines than in a conventional rod mill/ball mill circuit. A diagram of types of AG/SAG ...

II314 RoM Ball mills – a comparison with AG/SAG Milling Aubrey N. Mainza1 and Malcolm S. Powell 1 1Mineral Processing Research Unit, University of .

intermediate size ready for final grinding in a ball mill, pebble mill, or VERTIMILLTM. Wet grinding is accomplished in a slurry of 50 to 80 percent solids. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

In the case of SAB/SABC circuits the transfer size is the product of the SAG mill circuit and the feed of the ball mill circuit. Hence if powerbased equations such as eq. 1 and eq. 2 are

Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach. When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity. FullerTraylor SAG/AG Mills range in size from through in diameter with powers as high as 28,000 kW.

The SAG Mill is a machine added by Ender IO. It uses Redstone Flux (RF) to grind (or mill) items into their crushed variants, like Ores into Dusts. The SAG Mill has four output slots; recipes can have 14 different outputs, with different chances of obtaining those outputs.

BWI = Bond ball mill work index on SAG ground ore, kWh/ton ground F 80 = 80% passing of SAG ground of the test feed size, microns P 80 = 80% passing from the test product size, microns P cs = Bond closing screen size, microns G pb = Ball mill grindability (average of last three cycles), gr/rev Determination of the SAG and Ball Mill Pinion Energy :

The Mill Trunnion Liner fits inside the bearing to protect it from wear caused by the ore being washed over the liner and through the bearing as it is fed to or discharged from the mill.. The difference in the trunnions at each end of the mill isn''t in the trunnions themselves. The trunnion liner on the feed end of the mill may have a WORM to assist the ore into the mill.

WhatsApp)

WhatsApp)