(PDF) DESIGN AND FABRICATION OF MINI BALL MILL .

PDF | This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would ...

WhatsApp)

WhatsApp)

PDF | This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would ...

Figure 5. High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

These mills are of a special design and described on special request by all Ball Mill Manufacturers. Types of Grinding Mill Manufactured The different types of grinding mills are based on the different types of tumbling media that can be used: steel rods (rod mills), steel balls (ball mills), and rock material (autogenous mills, pebble mills).

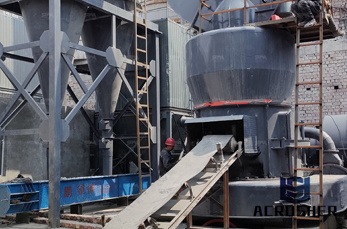

Ball Mill. Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other ...

To overcome these limitations in using modelling and simulation for designing ball mill circuits, a programme of research was initiated at the JKMRC in which it was proposed to use laboratory ball mill test results to calibrate a suitable ball mill mathematical model for .

Cement ball mill design huisarts vansichemnl. Nov 05, 2018ball mill design jaw crusher technology, small stone crusher plant Ball Mill Design Calculation Xls And PDF File Pressure Vessel Design[1] A ball mill is a The machinery and designs depicted in this book are copyrighted and or patented The designs Jan 14, 2014 cement ball mill design ...

The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

The Selection and Design of Mill Liners MillTraj. High–low double wave ball mill liners – These are a refinement of the wave liner, ... mill, corrosion environment, size of balls, mill speed, etc. liner design .

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

Dec 12, 2016· The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific ...

simple planetary ball mill design About simple planetary ball mill designrelated information:1 life john stuart mill was born in pentonville, then a suburb of london he was the eldest son of james, simple planetary ball mill design Size reduction and homogenization with ball mills.

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to be ...

Cement ball mill design huisarts vansichemnl. Nov 05, 2018ball mill design jaw crusher technology, small stone crusher plant Ball Mill Design Calculation Xls And PDF File Pressure Vessel Design[1] A ball mill is a The machinery and designs depicted in this book are copyrighted and or patented The designs Jan 14, 2014 cement ball mill design Online Inquiry

involve grinding). With Lloyd''s ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone. This article borrows from Lloyd''s research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball mill.

Design Of Ball Mill . All SAG and ball mill design methodologies are, All SAG and ball mill design methodologies are typically applied using a single design value for mill selection, such as the 80th percentile ball mill work index or SMC value Inherent in the selection of this design value is a desire for the mill .

Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure Ad this can be used to establish the essential features of a model for mill . Read More. calculation of ball mill design

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size.

Cement Ball Mill Design Pdf; Cement Ball Mill Design Pdf. The Selection and Design of Mill Liners MillTraj. Figure 5. High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot ...

towards steadystate design of grinding mill circuits. This study investigates simplified nonlinear dynamic models of grinding mill circuits suitable for process controller design. In the first part of this study, the number of size classes in a cumulative rates model of a grinding mill

how to design ball mill . ball mill,ball mills for sale,ball mill design, ball mill is an efficient tool for grinding many materials into fine powder, this machine runs stably and . get info simplified design of ball mill . Get Price. mineral processing, equipment manufacturers, ball mills .

Outokumpu''s mill group was created by combining the grinding mill business formerly know independently as , Morgardshammar an Scanmec with the Outokumpu mill business. Outokumpu (former Mills) was an early leader in the design and production of large road and ball mills for the mining industry and has

simple ball mill design shiatsudiemen. Simple Ball Mill Design aposproject. Ball Mill how to design – Grinding Mill China. All SAG and ball mill design methodologies are, All SAG and ball mill design methodologies are typically applied using a single design value for mill selection, such as the 80th percentile ball mill work index or SMC value Inherent in the selection of this design value ...

simple ball mill design shiatsudiemen. Simple Ball Mill Design aposproject. Ball Mill how to design – Grinding Mill China. All SAG and ball mill design methodologies are, All SAG and ball mill design methodologies are typically applied using a single design value for mill selection, such as the 80th percentile ball mill work index or SMC value Inherent in the selection of this design value ...

WhatsApp)

WhatsApp)