(PDF) Use of alternative fuels in cement industry

The utilization of alternative fuels in the cement industry since the 1980s was driven by rising energy prices, depletion of fossil fuels and the environmental impact of traditional fuels ...

WhatsApp)

WhatsApp)

The utilization of alternative fuels in the cement industry since the 1980s was driven by rising energy prices, depletion of fossil fuels and the environmental impact of traditional fuels ...

Cement industry overview by Goldstein Research contains global market trends, growth dynamics, challenges, key players and other statistics such as market size, share, revenue, cement production, sales, demand on global level with regional outlook for forecast period . Download sample report now!

The cement industry is the building block of the nation''s construction industry. Few construction projects can take place without utilizing cement somewhere in the design. Annual cement industry shipments are currently estimated at billion for 2012; up from billion in 2011.

Indian cement industry is the second largest producer of cement in the world just behind China, but ead of the United States and Japan. Also the industry is a significant contributor to the revenue collected by both the central and state governments through excise and sale. The industry occupies an important place in the national

taking place in the cement industry. UltraTech Cement acquired Jaypee Group''s cement business for US billion. Lafarge India sold its business to Nirma for US billion in 2016. Mergers Acquisitions In January 2017, JSW Cement bought per cent stake in Shiva Cement, for an estimate amount of US million.

The Indian cement industry is now globally competitive with lowestenergy consumption and CO2 emissions. Apart from fulfilling domestic cement requirements, the industry also exports cement and clinker to around 30 countriesacrossthe globe. The cement industry has evolved in the form of clusters across the country due to the concentration of ...

Apart from meeting the entire domestic demands, the industry is also exporting different varieties of cement and clinker. India is strategically placed to be a major exporter of cement in many countries. The export of Indian cement has increased over the years, mostly after decontrol, giving the much required boost to the Indian cement industry.

Cement industry ranks second after the Iron and steel industry. Cement is indispensable in building and construction works. The production and consumption of cement, to a large extent, indicates a country''s progress. The development of transport, infrastructure, irrigation and power projects etc. depends to a very large extent on the ...

production and excluded the emissions due to indirect energy (electricity, transportation, supply chain etc.) used for cement operations. This review observed a comprehensive literature in term of peer reviewed journals, industry sector reports, websites etc on cement industry and associated emissions and health impacts.

industrial case study: the cement industry calmac study id: final report prepared for pacific gas and electric company san francisco, california prepared by kema with assistance from lawrence berkeley national laboratory september 2005

Nov 18, 2019· Statista assumes no liability for the information given being complete or correct. ... available for direct download as PPT PDF! ... Cement industry in the

JUNE 2017 For updated information, please visit 3 EXECUTIVE SUMMARY Second largest cement market • With cement production capacity of nearly 420 million tonnes, as of FY201617, India was the 2nd largest cement producer in the world. The country''scement production capacity is projected to further increase to 550 million tonnes by 2025.

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of portland cement, and these

cement in the world. No wonder, India''s cement industry is a vital part of its economy, providing employment to more than a million people, directly or indirectly. Ever since it was deregulated in 1982, the Indian cement industry has attracted huge investments, both from Indian as well as foreign investors. Deloitte Risk Analytics Solution

Cement Kiln Optimization Controlling a cement rotary kiln is a very difficult task. The process is intrinsically unstable and there are long time delays and large perturbations acting on it. Only a perfect mix of experience, deep knowledge, mathematical techniques and stateoftheart software can achieve optimal behaviour over long periods ...

Aug 15, 2014· Cement is one of the basic materials in construction. However, it''s an essential item for development in the construction industry. Cement is .

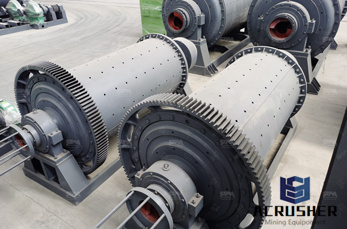

Volume 3, Issue 5, November 2013 388 hotair furnace may be used to supply this heat, but usually hot waste gases from the kiln are used. For this reason, the raw mill is usually placed close to the kiln preheater. Ball mill is used in cement industry. After the dry chamber material enters the 1st grinding chamber. 1st grinding chamber:

Tomar, MK 2014, ''Study of Occupational Health, Safety and Environmental Aspects in Major Cement Manufacturing Industry (Ultratech Cement Limited.)'', Journal of Environment and Earth Science, Vol ...

Currently, the cement industry is responding rapidly to the perceived societal need for reduced CO2 emissions by increasing the production of blended portland cements using supplementary ...

With 460 million tonnes per year (mtpa) of cement production capacity as of 2018, India is the second largest cement producer in the world and accounts for over 8 per cent of the global installed capacity, as of 2018. As of July 19, the production of cement stood at million tonnes. The cement ...

Cement Industry Introduction. Cement is a rocky powder that can be mixed with water and molded to any desired shape, after which it hardens to a rocklike consistency. It is used worldwide both as a mortar to join bricks and blocks together and as an ingredient of concrete, which is mixture of crushed rock, sand, and cement that is used to ...

To create the foundation for an industrywide climate change response strategy and manage the associated environmental and financial risk, ten of the world''s largest cement companies, under the ...

cement producers and the large plant builders in the cement industry. Level and pressure sensors have been used for many years in dižerent applications and areas of cement production: from crusher monitoring to controlling the filling of silos and vehicles. Maintenancefree and reliable Sensors for use in cement production must deliver accurate

Alternative Fuels in Cement Manufacturing 265 Cement production is an energyintensive proc ess consuming thermal energy of the order of GJ/tonne of clinker produced, which accounts for 30 40 percent of production costs (Giddings et al., 2000; EC, 2001). Worldwide, coal is the predominant fuel burned in cement kilns.

WhatsApp)

WhatsApp)