Pulverizers 101: Part I

Now suppose this same pulverizer must grind sufficient coal flow to produce full load on the boiler with fuel that is 40 HGI, still 3/4inch maximum size with 7% moisture, but with an increased ...

WhatsApp)

WhatsApp)

Now suppose this same pulverizer must grind sufficient coal flow to produce full load on the boiler with fuel that is 40 HGI, still 3/4inch maximum size with 7% moisture, but with an increased ...

the efficiency of existing coal fired plants. Operation of nonoptimized boiler can lead to reduced boiler efficiency, increased excess air requirements, delayed combustion, increased heat loss, high CO and NOx emissions and many other. Optimization of combustion in pulverized coal fired boiler is very important today for every thermal power plant.

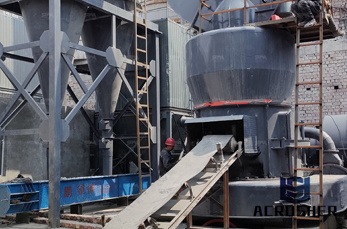

Nov 17, 2012· pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner ...

boiler, Coal, power plant, pulverizer. General System of Coal Pulverizer General System of Pulverizer. It is a positive pressure direct air swept pulverizing system with 5 HP963 medium speed coal pulverizers per boiler. Each pulverizer is equipped with one gravimetric coal feeder and one coal bunker. There are five independent pulverizing ...

Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a directfired coal burning system. 1 EPRI study on large coal fired utility boilers (greater than 600MW) using pulverizers with capacities

Aug 03, 2011· View inside Pulverized Coal burning boiler with hanging tube panels in center of boiler, dividing main 4 tube walls into two regions. Camera is in corner port of boiler, about 40 ft. above bottom ...

Our pulverized coal boilers currently allow for ramp rate as fast as 6% per minute and down to 20% for hard coal and 35% for lignite based on BMCR. Contact GE Power for more information on the use of boilers in steam power plants.

Dec 13, 2011· Boilers for steam generation in power plants and process industries use coal as fuel. The percentage of boilers operating with coal as fuel outnumbers the boilers using all other fuels combined. Coal is pulverized before firing for achieving a stable and efficient combustion. Many types of pulverizers are used in boilers by different designers.

In this system, each burner or a group of burners and pulverizer constitute a unit. Crushed coal is fed to the pulverizer through feeder at a variable rate governed by the pulverizer through feeder at a variable rate governed by the combustion requirements of furnace and steam generating rates required in the boiler.

Pulverized coal boiler is a kind of industrial boiler or power plant boiler that produces thermal energy by burning pulverized coal. Coal is ground to the size of a fine grain, mixed with air and burned in the flue gas flow. It is also known as pulverized coal furnace, powdered coal boiler or coal powder boiler.

PDF | Coalfired boiler systems generate approximately 38% of the electric power generation worldwide and will continue to be major contributors in the future. New pulverized coalfired systems ...

Boilers machinery : Coal Pulverizer [ Thermal Power Plant] [ ENERGY] Pulverizers (coal pulverizer) are used to pulverize pieces of coal into fine particles (100μm) before placing into a boiler, to ensure efficient combustion.

Nov 02, 2017· Pulverized Coal Feeding Handling System Duration: ... This video describes the complete demonstration that how coal fired boiler actually works by an animated video ... Coal Fired Power Plant ...

Jan 15, 2019· Pulverized coalfired Boiler or Pulverized fuel Boiler. A pulverized coalfired boiler is an industrial boiler that generates thermal energy by burning pulverized coal. How does a steam boiler work? In pulverized coal fired boiler,The coal is pulverized to a fine powder, so that less than 2 % is +300 micro meter and 70 – 75 % is below 75 microns.

Producing electricity in coal power plants can take place in a number of ways with varying degrees of efficiency. In conventional coalfired plants coal is first pulverised into a fine powder and then combusted at temperatures of between 1300 and 1700 o C. This process heats water in tubes in the boiler so that it becomes steam at a pressure of around 180 bar and a temperature of 540 o C.

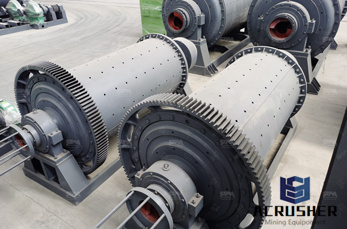

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer puritch is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants

With more than a century of experience, Riley Power Inc. is a highly respected manufacturer of steam boiler parts and fuel burning equipment for all types of fossil and waste fuel fired boilers, including those that fire coal, oil, gas, as well as waste fuels including refuse, wood and cellulose byproducts.

Reliable coal pulverizer performance is essential for sustained fullload operation of today''s power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW.. BW''s pulverizers, found at power stations throughout the world.

A boiler or Steam Generator (prime mover) is an integral device in a fossil fuel power plant used to produce steam by applying heat energy to water. A boiler incorporates a furnace in order to burn the fossil fuel (coal, gas, waste etc.) and generate heat which is transferred to water to make steam.

This time, however, is dependent on various factors. The heart of a pulverized coalfired boiler is the pulverizer, also known as the mill. Depending on speed pulverizers are classified as lowspeed, mediumspeed, and highspeed mills. Pulverized coal burners may be located on the front or opposed walls or in the corners of the furnace.

Coal pulverizers are the heart of a pulverized coalfueled boiler. Often, the root causes of nonoptimized combustion lie with the pulverizers. ... Mill power to ton of coal throughput.

Coal pulverizer explosions occur frequently and in 1999 an explosion at a Georgia power plant injured seven employees, one of whom died from his injuries. ... a single power boiler incident ...

the equipment is considered in the auxiliary power requirements. BOILER SYSTEM The total number of pulverizers (including one spare) and their associated power requirement is based on plant size and coal type. The 400MW plant uses five pulverizers for bituminous and PRB cases, and six for lignite; the

Thermal power plants use different types of coal pulverizers. The method used is attrition, impact, or a combination of both. This article explains the characteristics of the three main types attrition, impact and attrition, and impact or hammer. Selection of the type of pulverizer depends on the grindability of the coal, the capital costs and maintenance costs, and considerations for licensing.

WhatsApp)

WhatsApp)