Gold Mining Classifier Screen Water Recycler Invention ...

Sep 29, 2017· This was my first prototype of a displacement based water recycler, designed to transfer water from one bucket to another while you''re classifying material .

WhatsApp)

WhatsApp)

Sep 29, 2017· This was my first prototype of a displacement based water recycler, designed to transfer water from one bucket to another while you''re classifying material .

Classifying material when gold mining gold mining what is classifying regencypark co gold mining equipment ore classifying mining double gold mining processing plant copper ore beneficiation Yantai Xinhai Mining Group Company is the first company to provide EPC service in China and has finished more than 500 EPC all over the world .

Classifying (sizing) your material to the proper dimension is also essential to any successful fine gold recovery operation. Remember, for best results reduce the size of your material to the approximate size of the gold you expect to recover, and you will increase your gold recovery rates greatly.

Gold panning is the most common method used by small scale prospectors, but larger mining equipment like gold dredges, sluice boxes, drywashers, and many other types of equipment uses gravity separation to discharge lighter material while retaining gold.

Mining Gold Equipment: What Tools Do I Need For Gold Mining? The type of tools that you will need for gold mining depend a great deal on the type of mining that you have in mind. If you are just out for a day of entertainment to chance your arm in one of the free to prospect rivers then you will need only very basic gold prospecting supplies.

The Earthquake Vibrating Bucket Gold Classifier by BBR Prospector Mfg ... the secret is to MOVE MATERIAL. The "Earthquake" will classify a 5 gal. bucket of dry or wet material in 3 to 5 minutes, and no stooping, ... The EARTHQUAKE is THE machine for fine gold recovery. Easily classify all the way to .

This one is 1/2 inch mesh, meaning that it will screen out anything larger than 1/2 inch. It''s not absolutely necessary to use a classifier, but it does help a lot by keeping big junk rocks out of your pan and just letting through the smaller material more likely to contain gold. I do my classifying under water.

A musthave tool for rock hounding, gold and gem panning and proper classification of material to aid in fine gold recovery. Various screen / mesh sizes are available. Special offer: SAVE MORE! Order one of our sets or all 9 classifier sizes for a reduced rate and you also pay just the single item shipping rate! CHOOSE SET OPTION IN THE DROP ...

The Extractive Metallurgy of Gold Gold Deposits Types: List of 10 Gold Deposit Class #1 Pegmatites are igneous rocks formed in the final stage of magma crystallization Porphyry Dyke Coarsegrained granite Albitite Gold Deposit Class #2 Carbonatite Carbonatite Related Gold Deposit Class #3 Auriferous Gold Skarn Type Deposit Gold Deposit Class #4 ...

This Classifying Sieve enables you to classify your material before processing it through your sluice box or gold pan. Made of highimpact plastic and .05 inch stainless steel mesh, this sieve will save you time and improve your recovery.

Aug 13, 2019· Ore screening is to screen and separate the material with a particle size below 250 um, among which the classification of materials below 10 um is called superfine classification. Ore classification affects the crushing and grinding process and controls the particle size of the final product, which in particular plays an important role in product quality.

Dec 27, 2015· Nearly all professional gold placer mining operations classify their gravel to maximize the amount of gold that they recover. Doing this step prior to running material through a sluice box allows for maximum retention of gold, especially the finer gold dust. Classifying gravel is the process of separating the aggregate material into consistent sizes by .

gold mining hydro sizer for gold slurry classifying. Gold Mining Hydro Cyclone Separator,Find Complete Details about Gold Mining . Material in the rotor role to achieve a preclassification, such that the first . to adapt to the new standards for cement particle size distribution requirements.

To improve gold recovery, it is common practice to run material through a screen to classify out the larger rocks before running the material through the recoveryportion of a sluice box. In this way, less water velocity is needed through the box, which allows for a more orderly flow, and an increase in fine gold .

Using a dry washer is a great way to find gold in many areas in the southwest. Limited water makes gold prospecting difficult in many regions, making common mining methods like panning, sluicing, and dredging impossible. They are a great way to find gold in .

The HOGPAN™ – Patent Pending The first hybrid gold pan / highbanker that is still a "gold pan" but increases production up to 10 fold. Now prospectors can REALLY get good gold from areas with restrictions on equipment. Self classifying, fluidized lower capture chamber, GOLDHOG

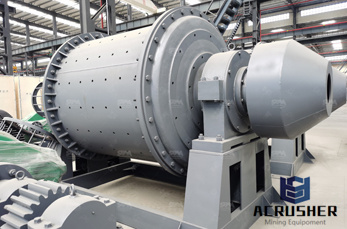

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Classification is the Key to Fine Gold Recovery. It is wellestablished that if you want to effectively recover finer particles of gold, you must first separate them from the largersized materials which are being washed through your recovery system by a highervelocity flow of water. The smallsized material can then be directed to a milderflow of water over a shorter set of riffles.

Some method of screening is necessary to "classify" the sizerange of materials that you want to direct into each type of recovery system. The more that different sizefractions of material are separated from each other, the easier it is to separate gold or gemstones from the other materials .

Mineral resource classification is the classification of mineral resources based on an increasing level of geological knowledge and confidence. Mineral deposits can be classified as: Mineral resources that are potentially valuable, and for which reasonable prospects exist for eventual economic extraction.

Classifying Material When Gold Mining. Goldauriferous deposits can be classified into types for which here is a list of 10 types of gold deposits auriferous porphyry dykes sills and stocks auriferous pegmatites coarsegrained granitic deposits albitite carbonatites and carbonatiterelated,Classifying material when gold mining.

However, further classifying the material with finer mesh sizes would further reduce the amount of junk you have to pan through to get to the gold. A lot of experts recommend classifying down to much smaller mesh sizes in several stages, carefully examining what remains in each classifier for nuggets at each step of the way.

PORTABLE GOLD PAN. with cross flow design. The Gold Pan that takes gold panning into the next generation. Combines the panning action with a cleaning flow of a sluice. The PATENT PENDING FLOWPAN ™ is the next generation of panning. It could very well be the WORLD''S FASTEST GOLD PAN. Watch the videos and read the story HERE

The basic materials sector is a category of stocks for companies involved in the discovery, development, and processing of raw materials. The sector includes companies engaged in mining and metal ...

WhatsApp)

WhatsApp)