PULVERIZER PLANT | COAL MILL | WORKING with major ...

Aug 18, 2018· [hindi] thermal power plant ~ basic information ~ introduction of thermal power plant for freshers duration: 10:35. Let''s Crack GATE ESE ME 246,696 views 10:35

WhatsApp)

WhatsApp)

Aug 18, 2018· [hindi] thermal power plant ~ basic information ~ introduction of thermal power plant for freshers duration: 10:35. Let''s Crack GATE ESE ME 246,696 views 10:35

Filter Bag for Cement Plant During cement production process, there is a lot of dust and gas emissions outwardly, there are many different filter bags can be chosen for meet varied working condition. Capacity: 2000 pcs per day

Raw mill exhaust fans are operated with very adverse situations because the fan handles mainly gases such as CO2, N2, NOx and Sox along with some dust particles. Coal Mill Fans. In cement industry coal mill fans are used to supply required air for burning coal and remove the exhaust gases produced after burning.

This paper mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder. This is achieved in a cement raw mill.

Each plant is fired with subbituminous coal from the powder river basin (PRB) (see Table for coal properties) and sized to generate 750 MW of net power. The flue gas temperature exiting the air heaters of all four boilers is 121 °C (250 °F) and the boiler efficiency is % (HHV).

Refusederived fuel (RDF) is a fuel produced from various types of waste such as municipal solid waste (MSW), industrial waste or commercial waste.. The World Business Council for Sustainable Development provides a definition: "Selected waste and byproducts with recoverable calorific value can be used as fuels in a cement kiln, replacing a portion of conventional fossil fuels, like coal.

Cement mill Wikipedia

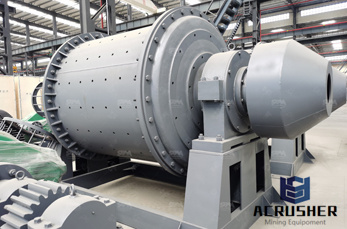

May 19, 2006· Types of coal pulverizers. Coal pulverizers may be classified by speed, as follows: Low Speed; Medium Speed; High Speed; Low speed Ball and tube mills. A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods.

Great Wall is the professional manufacturer of cement machinery with the production experience for more than a half of century. Our company put forward a suit of highly effective solution for frequently asked questions in the process of cement production. This solution can effectively reduces power consumption and dust pollution of cement plant, reduces manual operation, .

Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range. Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs.

A cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces is the most widely used material in existence and is only behind water .

Coal Mills for Cement Plants Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations.

Cement Plants located in United States. Switch to statistics view. Cement plant locations and information on United States can be found below. For full access to the database, purchase The Global Cement Report™, 13th Edition. Purchase. Summary; Cement capacity (Mt)

Energy and Exergy analysis of the Raw Mill in the Cement Plant 51 raw mill unit of the plant is conducted by using the actual plant operational data. About the Plant The typical plant selected for the case study is located in Palakad district, Kerala. It is a public sector company fully owned by the Govt of Kerala.

Coal mill pulverizer used in cement plantCoal grinding mill for sale Coal mill is the machine used in cement mill manufacturer Caiman Machinery Ycdc Cement Plant In Myanmar Gaur Grandeur . What Is Coal Mill In Cement Plant In Myanmar. Continous Rolling Mill Stand, ycdc cement plant in myanmar rolling mills in pune for sale. materials can be crushed in myanmar coal

Types Of Coal Mill Used In Cement Plant Types Of Coal Mill. LUM vertical roller mill is used to pulverize and dry coal before it is blown into the power plant furnace in the coalfired power plants.; As we all know coal production line is with serious pollution, In order to provide a environmental friendly coal grinding mill for customers, MTW trapezium mill is designed with .

Changshan South Cement, China benefitted from a costsaving energy retrofit of its two clinker production lines with raw mill circulation fans. Raw Mill Fan Dunbar Cement At Tarmac (Dunbar cement plant, UK), their existing Raw Mill fan was replaced with an enhanced Howden design in 2007.

The plant is also supported with two coal based captive power plants with 15 MW and 60 MW capacities, located within the cement plant complex. A separated railway siding is established from Mellacheruvu Station connecting Jaggayyapet Station for .

Apr 30, 2019· Type: Cement Plant. Area: Missouri. Annual Production: 4 million tonnes of cement. Owner: Holcim (US) Inc. Shareholders: Holcim Limited. Activity Since: 2009

Most commonly used mills for coal grinding in cement plants are closed circuit air swept (Single chamber) ball mills and vertical mills. Ball Mill: Single chamber ball mills (with classifying liners and dam ring) with drying chamber and static or dynamic separator are commonly existing for coal grinding in cement plant for one or more kilns as ...

Feb 23, 2016· Coal mill fans: In cement industry coal mill fans are used to supply required air for burning coal and remove the exhaust gases produced after burning. These fans help in effective burning of coal inside the mill. For a large clinker line there are usually 2 or 3 cement mills.

Coal Mills LOESCHE Innovative Engineering . Coal Mill Loesche Mill Type LM Dillingen components that have been employed for decades in Loesche mills in the cement industry. Get Price; Handbook on Cement Plant Design Scribd. Handbook on Cement Plant Design Ebook download as PDF File (.pdf) Text of Mills Layouts of Coal ...

Typical plant energy conservation projects: • Modification of the coal mill for operation with preheater exhaust gas for high volatile coal and utilization of 14 % RDF in the pyrosystem. • Increase of efficiency and capacity of preheater, calciner and cooler.

Pennsuco Cement Plant Titan Florida''s Pennsuco cement plant, located west of Miami recently completed its modernization project that increased production capacity to million tons annually. It is now the largest cement facility in Florida and is recognized as one of the most environmentallyfriendly and efficient plants in the United States.

WhatsApp)

WhatsApp)